Minimising liability risks – quality management and assessment solution launched at ProPotsdam GmbH

It is not only important to ensure that the quality assessment

inspections are carried out on a regular basis; documentation and archiving are

also crucial. After all, if damage or injury occurs in connection with the

property, the owner must be able to prove that suitable safety precautions were

in place at the real estate object. Such inspections are not a major challenge

for companies with small portfolios. However, as the size of the company

increases and the real estate portfolio grows, the numbers of objects to be

inspected, inspection tasks to be performed and inspectors involved also

multiplies. In some instances, external companies perform various quality

assessment tasks, although the monitoring and management obligations always

remain with the owner. The quality assessment obligation is thus an

increasingly complex task. This was a challenge also faced by

ProPotsdam GmbH. “With a portfolio of almost 17,000 apartments, it was

time for a rethink. We needed to find new methods that would make it easier to

organise and map the inspection obligations and facilitate implementation and

archiving. With this in mind, we developed a future-oriented solution together

with our long-term business partner PROMOS,” explains Monika Gräf, head of

information and communications at ProPotsdam GmbH.

ProPotsdam GmbH is the largest housing company in Potsdam, the

capital of Brandenburg, and the leading service provider for urban renovation,

urban development, residential construction and housing assistance. A total of

11 subsidiaries are housed under the ProPotsdam GmbH umbrella. The company

contributes to sustainable and future-oriented development in the construction

and housing sector with innovative concepts and socially responsible conduct.

In close collaboration and agreement with PROMOS, the project managers at

ProPotsdam GmbH created a new concept for holistic fulfilment of quality

assessment obligations. The requirements for the new system focused not only on

minimising costs and workloads in general while increasing transparency, but

above all on end-to-end digital processing of the process, including

involvement of all internal and external parties and complete SAP® integration.

Another key focus was automatic and audit-proof archiving of inspection

reports, as this is the only way to counteract any potential liability claims

in the event of damage. These arguments served as the foundation for the

solution throughout the entire duration of the project, and the result

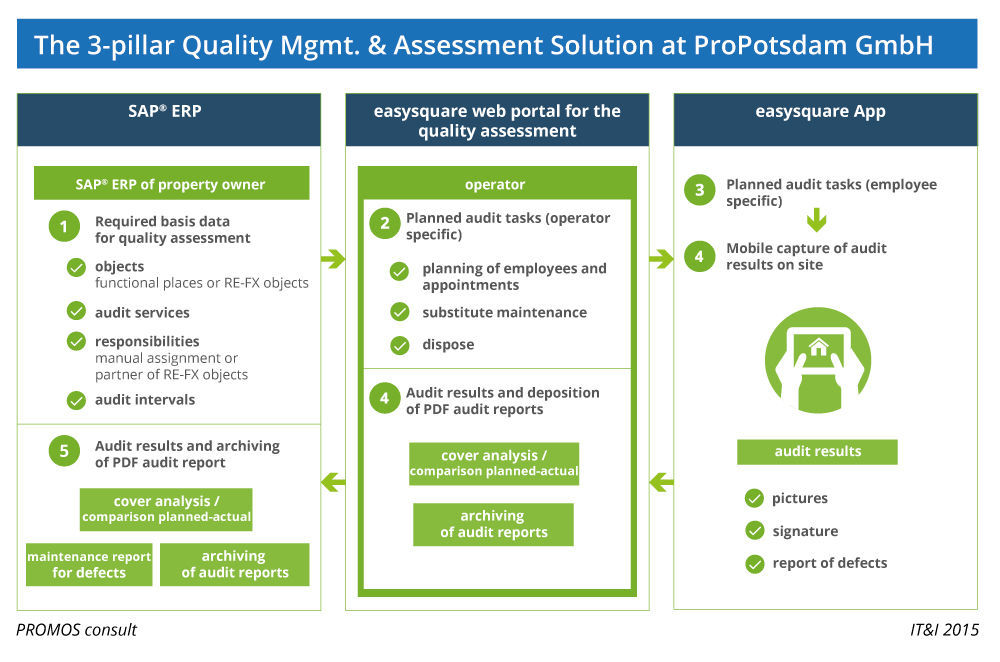

succeeding in meeting the high internal expectations. The three-pillar quality

management and assessment solution based on easysquare is the right tool for

any group of users to perform their respective tasks:

- The SAP® system is a central hub and archiving location for ProPotsdam

- The easysquare platform is a management tool for external service providers

- The easysquare mobile app is used to carry out pending inspection tasks on site using a mobile device

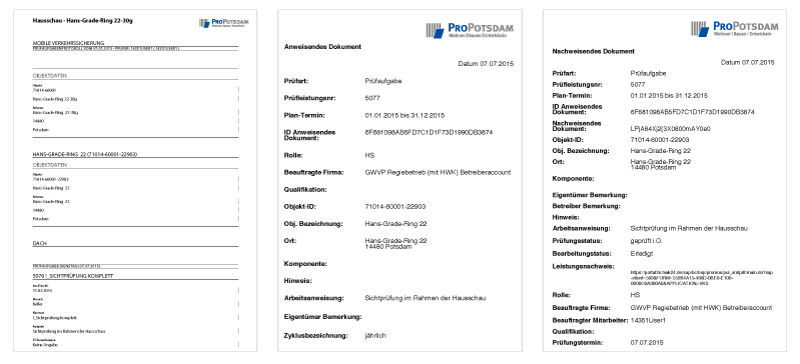

Figure 1: Data is exchanged using the easysquare web portal with the aid

of a ready-to-use plug-in for connection to the owner’s SAP® system. |

“Ultimately, the key to success was a combination of mobile terminal devices and complete integration of SAP®. This is the only way to map existing quality assessment obligations holistically across the entire process,” says Torsten Friedel, project manager and COO at PROMOS.

Process organisation with SAP® and the easysquare web portal

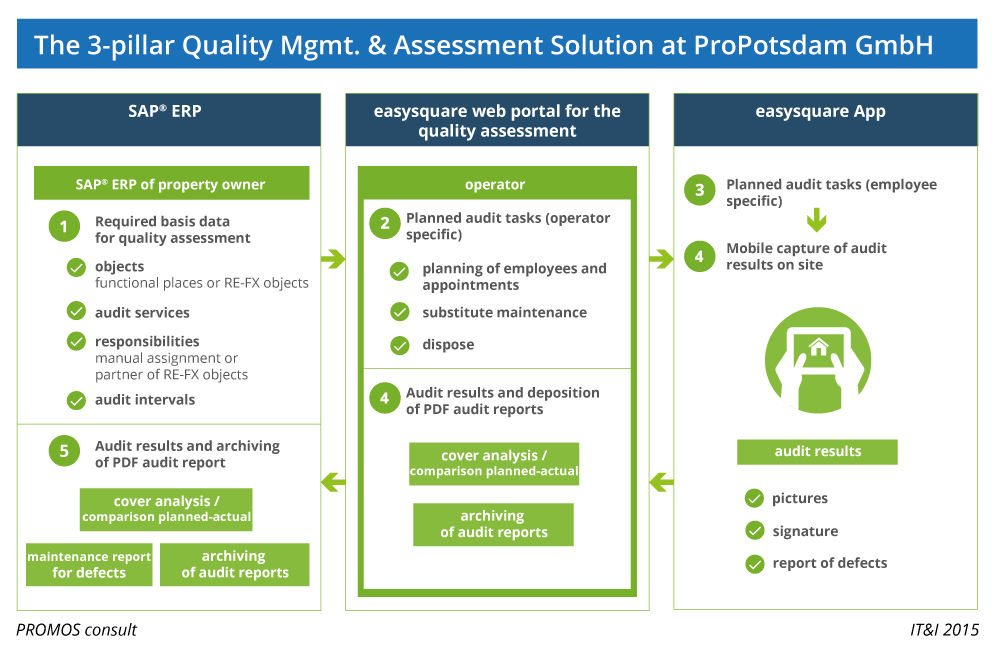

Today, employees at ProPotsdam literally make short work of organising

their quality assessment obligations. In just a few clicks, processors can

assign existing inspection obligations to individual buildings and their

respective operators from within their SAP® systems. Examples include a visual

inspection of a building or check of a gutter, which a certain operating

company needs to perform on building XY. The idea behind the process: Why not

select and assign the inspection obligations in the same place that the master

data for the objects is stored? This saves time and also reduces susceptibility

to errors by avoiding media discontinuities. A particular advantage is also

that the inspection cycle for the individual inspection obligations is already

stored, so the employee in question does not have to make any more adjustments.

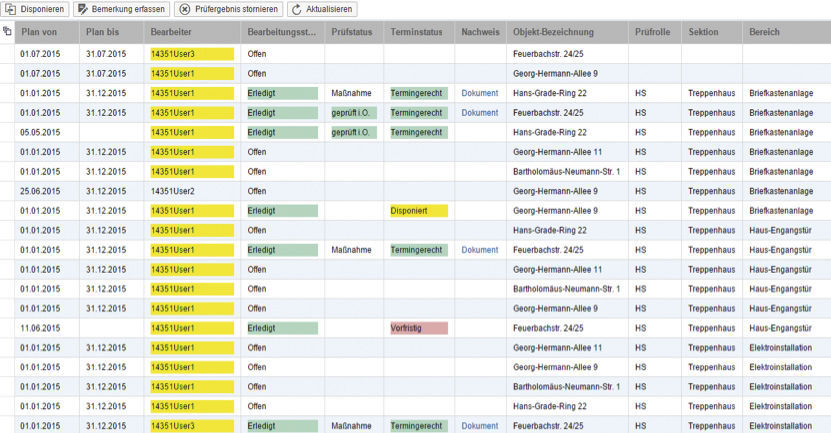

So how does the on-site quality assessment actually work? Digitally, of

course! Imagine that the quality assessment inspectors receive the inspections

perform on their iPad from the MRP planner or the portfolio assignment. Just

like in an e-mail program, the inspectors can now see in the mailbox all the

inspection tasks that are to be completed. The easysquare mobile app also

provides information as to where, how and within which timeframe these tasks

have to be performed. Using the integrated map function, our inspectors can

plan the day’s journey with ease and find their way to the first property. They

stand in front of the building, perform an initial visual inspection of the

property in accordance with the task, check that everything is okay and then

make a note of this by simply tapping checkboxes in the easysquare mobile app

form. The next task might be to check the gutter. They then inspect this

carefully based on the work order shown on the mobile device. If there is a

defect or the gutter is blocked, they can take a photo of the fault using the

app and add a description text, for example. At this point, they set the

inspection result to “Not okay”. The fault registration subsequently results in

automatic generation of a report in ProPotsdam GmbH’s SAP® system. The inspector

is now finished with the assigned inspection tasks. The digital form with the

inspection results is once again sent directly to the easysquare web portal,

where it is saved as a PDF inspection report.

Last stop: Checking and archiving

Immediately

after a digital form is sent, employees of ProPotsdam GmbH can access the

inspection report in the SAP® system. All inspection results, photos and the

inspector’s signature are contained in the document automatically and can be

viewed. The employees thus have the opportunity to check the quality

assessments that have been performed. “Results do not have to be manually

transferred to the SAP® system, which saves our employees a lot of time and

effort. At the same time, the inspection reports are automatically archived in

an audit-proof manner, allowing us to develop the documentation of our quality

assessment performance in line with the law,” emphasises Robert Bolduan, head

of the Technical Facility Management department at ProPotsdam subsidiary

GEWOBA. However, if the worst comes to the worst in the event of damage, the

inspection reports are not the only thing available to ProPotsdam GmbH as

evidence that the company has met its obligations. An additional instruction

and evidence document can also be generated in the SAP® system. This documents

that the inspection task was assigned and fulfilled based on the inspection

results.

Conclusion: A sound solution

The

easysquare quality management and assessment solution at ProPotsdam GmbH

is designed to map the entire quality assessment process seamlessly, from

instructions to audit-proof documentation. The avoidance of gaps in the process

and the high degree of interaction not only save effort and time, but above all

ensure precise documentation of the quality assessment inspection performed. In

their search for a new, straightforward solution, ProPotsdam GmbH found a

holistic and reliable solution in the quality management and assessment

solution. In the future, alongside the building inspection, further processes

(such as caretaker services) are to go live in stages. The solution is also

scalable in the event of further growth – whether it be enhancement to

include additional quality assessment processes, new operators or further real

estate objects. With the quality management and assessment solution based on

easysquare, ProPotsdam GmbH is equipped for the future.

redaktion@openpromos.de